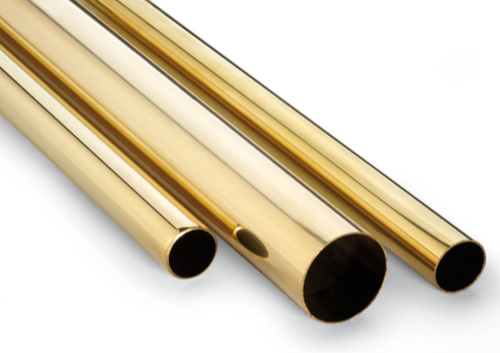

At Metal Alloys Corporation, we take pride in being a leading manufacturer of C44300 Admiralty Brass Tubes. With a commitment to quality and precision, we strive to deliver products that exceed industry standards. Backed by years of expertise, we have established ourselves as a reliable partner for businesses seeking top-notch brass tubes for various applications.

Our C44300 Admiralty Brass Tubes are crafted with precision and adhere to strict alloy specifications. The alloy is carefully formulated to ensure optimal performance and durability in diverse industrial settings.

Our C44300 Admiralty Brass Tubes find applications across a wide range of industries, including but not limited to:

Our C44300 Admiralty Brass Tubes are manufactured with a precise chemical composition to meet the highest industry standards. The composition is tailored to provide corrosion resistance, thermal conductivity, and overall reliability.

C44300 Admiralty Brass is a copper-zinc alloy with small additions of arsenic and tin. The chemical composition of C44300 Admiralty Brass is typically as follows:

These percentages can vary slightly depending on the specific production and manufacturer specifications. Admiralty Brass, including C44300, is known for its corrosion resistance, excellent thermal conductivity, and suitability for various industrial applications, particularly in heat exchangers and condenser tubes in marine environments.

Our brass tubes undergo rigorous testing to ensure they meet the required mechanical properties. This includes tensile strength, yield strength, and elongation, guaranteeing a product that stands up to the most demanding conditions.

The mechanical properties of C44300 Admiralty Brass are crucial for understanding its behavior under different conditions. Here are typical mechanical properties for C44300:

These values provide an overview of the material’s strength, ductility, and other mechanical characteristics. It’s important to note that these properties can be influenced by factors such as the manufacturing process, heat treatment, and the specific application conditions.

When using C44300 Admiralty Brass in engineering or manufacturing applications, it’s advisable to refer to the specifications provided by the manufacturer or industry standards to ensure the accurate properties for the specific product you are working with.

We offer a comprehensive range of sizes to cater to diverse industry needs. Whether you require small-diameter tubes for intricate applications or larger tubes for industrial-scale projects, we have you covered.

In addition to our flagship C44300 Admiralty Brass Tubes, we also offer products that conform to other similar standards. Our commitment to quality extends across a range of brass alloys to meet the varied needs of our clients.

C44300 Admiralty Brass is primarily an American standard, and finding an exact match in other international standards like ISO, DIN, JIS, EN, or BS may not be straightforward. However, you can find similar brass alloys in these standards that share similar characteristics and properties. Here’s a general guide:

When looking for alloys similar to C44300 in these standards, pay attention to the alloy’s chemical composition, mechanical properties, and application suitability. It’s recommended to consult the specific standards or work with a materials expert to ensure compatibility for your intended use.

Discover the quality and precision of our C44300 Admiralty Brass Tubes. Contact us today to discuss your specific requirements and explore how we can be your trusted partner in delivering top-notch brass tube solutions.

Contact us for more Details and Offer Quotation bdm@metalalloyscorp.com Or for Quick Access contact on Whats Application.